Choosing the Right Marker

Choosing the right marker for a pole marking system involves several key considerations. The marker must effectively fulfill its primary purpose of clearly marking the pole for easy identification. It should also be legible under various field conditions, ensuring readability even in challenging outdoor environments. Durability is another crucial factor, with the marker needing to withstand UV radiation, pollution, temperature extremes, and potential vandalism. Additionally, the cost of acquisition and ownership, including labor and maintenance expenses, should be taken into account.

Legibility

No pole marker can perfectly meet all the requirements. When choosing a pole marking system, trade-offs between legibility, durability, and economy must be considered.

Legibility is crucial, as the human eye requires adequate light and contrast to discern objects. Larger objects are generally easier to see than smaller ones, including pole markers. For example, someone with 20-40 vision can typically see a 1″ tall marker from 28 feet, a 2″ marker from 56 feet, and so on.

During the day, sunlight can be excessively bright, causing flat pole markers made of shiny materials (such as mylar, aluminum, or reflective sheeting) to reflect sunlight excessively and become unreadable. To ensure legibility, markers with multiple planes, such as embossed, stamped, or debossed markers, should be considered. A simple color contrast on a flat surface is often insufficient for guaranteeing legibility.

At night, visibility is reduced as our light sources, such as street lamps, headlights, or flashlights, are not as strong as the sun. The legibility of a marker depends on factors like distance from the light source, weather conditions, and the angle between the light source, marker, and our eyes. Reflective glass beads or sheeting can enhance legibility, but the effectiveness depends on the strength, focus, and angle of the light source relative to the marker. Reflectivity should be balanced, as excessive reflectivity can create difficulty in reading the characters due to surrounding glare.

Durability

Durability is a crucial aspect when it comes to pole markers. They can be made of different materials, including plastics, laminates/composites, or printed/painted products. While plastics have been marketed as strong alternatives to traditional materials, they are still susceptible to UV radiation. The sun’s UV rays can degrade plastics over time, resulting in fading, cracking, and brittleness.

In contrast, metals have proven their durability outdoors, with steel markers being prone to rust and brass markers being expensive. Bronze and zinc markers are easily damaged, while aluminum stands out as a suitable material for outdoor use. Aluminum does not rust and possesses good tensile strength. Upon exposure to air, it forms a protective layer of aluminum oxide that prevents further reaction. For more information about aluminum, click here.

Paints and inks are used to provide contrast on certain pole markers. Both consist of pigments and other substances that bond to the substrate material when applied and dried. In general, paint layers are thicker than ink layers, and paint exhibits greater bonding strength (coefficient of adhesion) compared to ink. The quality of paints can vary based on the economic choices made by manufacturers regarding pigments, plasticizers, solvents, and UV inhibitors. Higher-priced paints typically offer better durability outdoors. The skill and care of the individuals applying the paint or ink, as well as the cleanliness of the application facility, are also important factors influencing the outdoor durability of painted or inked markers.

Economy

When considering the economy of a pole marking system, it is important to note that the labor cost associated with attaching and maintaining the system far exceeds the acquisition cost of the markers themselves. Ideally, one should aim to specify and purchase a marking system that offers longevity and requires minimal maintenance. However, it is ironic that many electric utilities prioritize initial acquisition cost and purchasing budgets when selecting a pole marking system, which may explain why there are only three manufacturers of porcelain steel signs remaining in the United States.

In conclusion, there are trade-offs to consider based on the discussed facts. If reflectivity is desired, it must be accepted that the marker may have a shorter field life (even 3M, the inventor and largest supplier of reflective sheeting, guarantees its product for only 7 years of outdoor use). Opting for a painted product with high contrast requires using top-quality paint applied by skilled individuals, but it should be acknowledged that even the best paint will fade due to the stronger UV radiation. Choosing inexpensive plastic, heat-stamped markers provides economy but comes with the drawback of peeling, cracking, and fading within a few years. For complex, multi-character alphanumeric coded markers, a slide-in system is recommended, but it should be acknowledged that human error and mistakes can occur, leading to incorrect or missing markers.

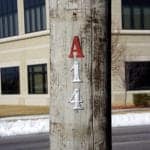

Considering all the trade-offs, the best marker solution is the Premax embossed, solid aluminum letter or number, securely fastened to the pole with a Premax bright galvanized steel nail. This marker will endure for the entire life of the pole. Made of aluminum, it is resistant to rust, cracking, fading, and illegibility. The embossed design ensures reflection of the sun’s rays or a flashlight’s beam from multiple angles, without causing blinding glare like a mirror.

With over 80 years of experience, we have manufactured over 800 million of these pole markers, all proudly made in the United States of America.